Smithstown’s Wire EDM experience stretches back over 35 years to 1987, with the then very new technology allowing Smithstown to produce forms in Dies and Mould Cavities to an accuracy that was previously unattainable. We quickly mastered the technology and the Wire EDM department grew to become a backbone within Smithtown’s Medical Device business. It continues to be a core competency within the business and now Smithstown is future proofing and taking its Wire EDM capability to the next level of accuracy, reliability and performance.

Through a key partnership with Makino, we’re in the process of upgrading our Wire EDM fleet with the installation of 6 new Wire EDM’s and two more due in November. View video

Supported by Makino’s Irish agent and representative, Machine Tool Technologies Ltd, these machines come from the U6 and U3 H.E.A.T range and come with glass scales providing 0.001mm positional accuracy. The latest generator technology slashes cut times by over 35% with lower energy costs and less use of Wire. The machines come equipped with rotary 4th Axis units allowing for un-maned changes of the workpieces angle, leading to much longer machine-up times.

Six of these machines are now installed and operational, with a further two machines to be delivered at the end of 2022. On completion, our Wire EDM capacity will grow to 1,344Hr’s per week, giving us production capacity and surge capacity for existing medical device customers.

To find out more or request a consultation, please contact us at info@sle.ie

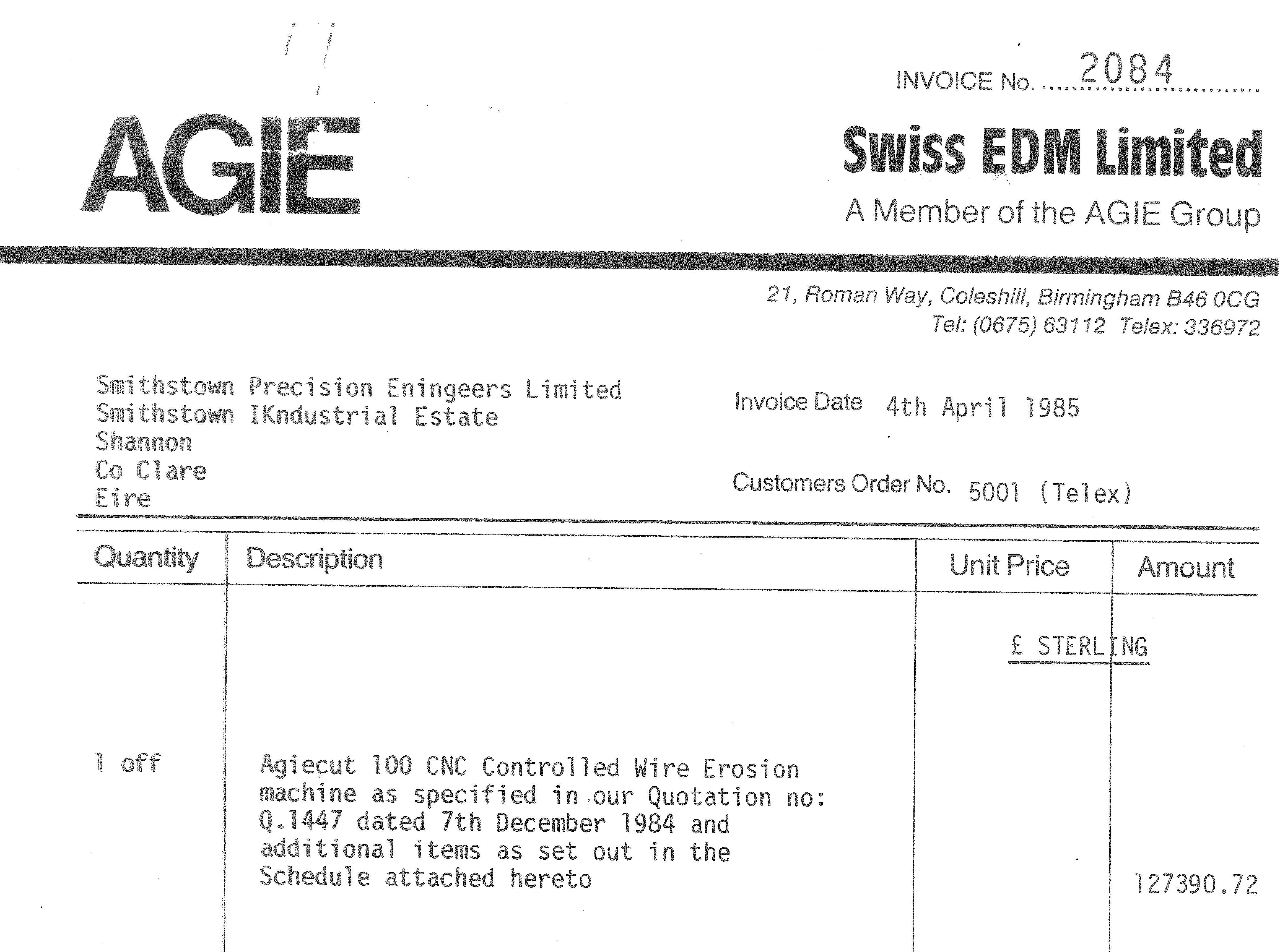

Here’s our first invoice for a Wire EDM dating back to April 1985!