Additive Manufacturing

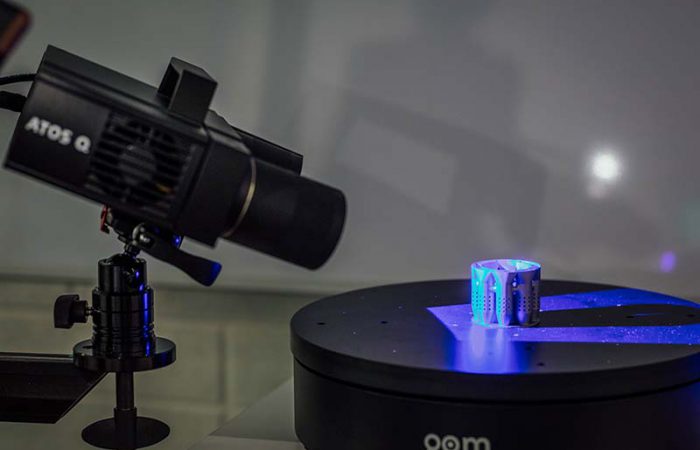

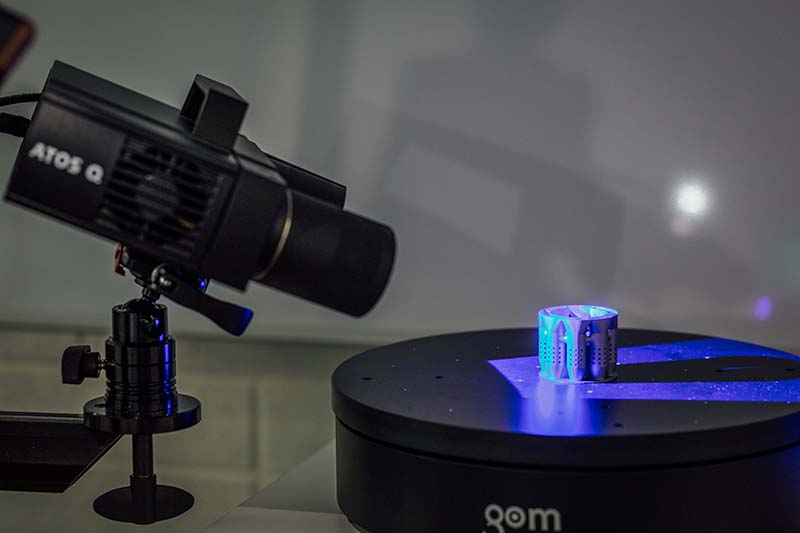

Through our new state-of-the-art Additive manufacturing facility, we are helping customers develop better products for real-world applications.

From design assessment and validation, through to post production finishing, we can reduce costs, drive greater efficiencies, minimise risk and open new areas of growth.

We have invested in world leading technologies, our people and our processes to bring the whole additive manufacturing technology process under one roof.