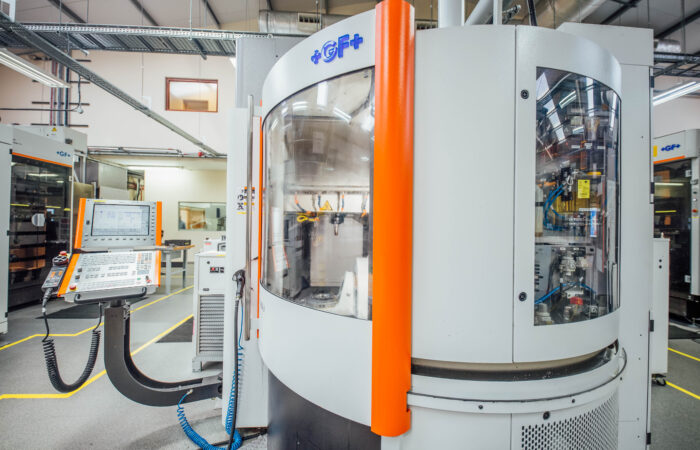

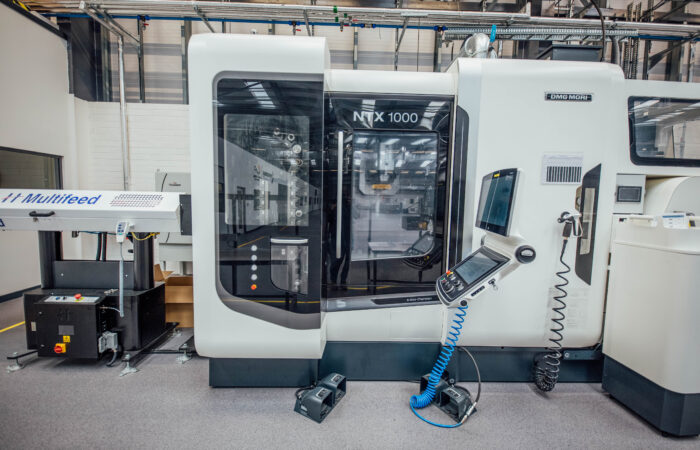

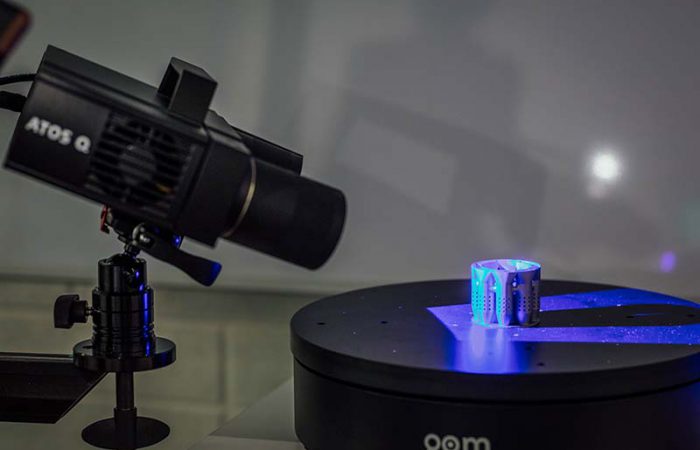

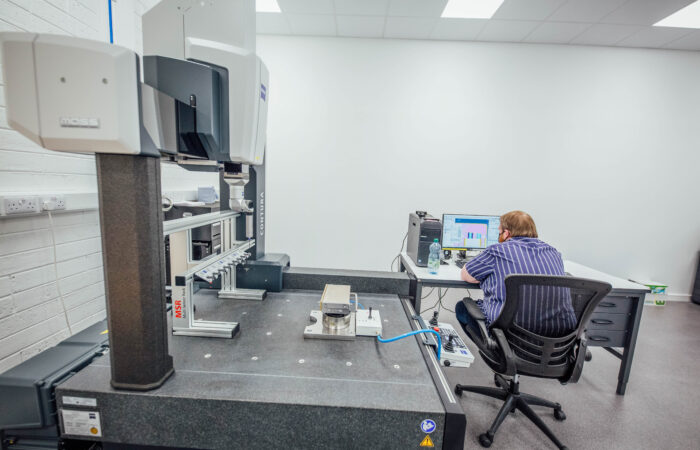

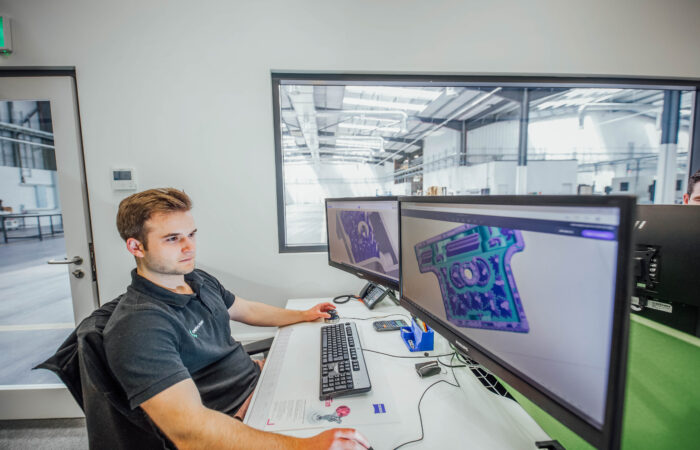

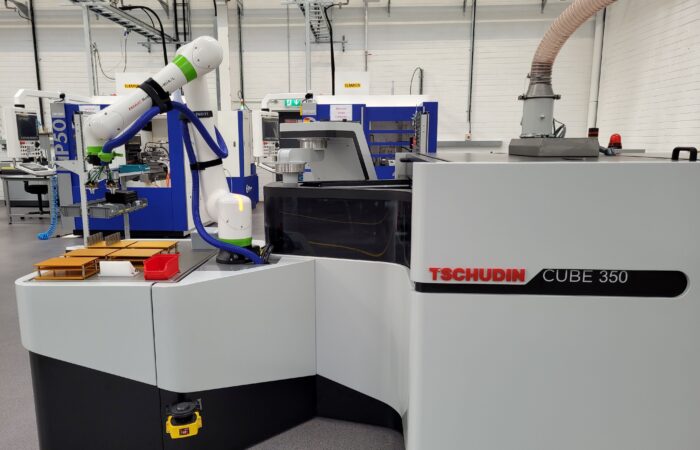

Our Equipment

To keep up with our clients growing demand for ultra precision products used in lifesaving treatments, we continuously invest in our facilities, equipment and people. We now have two manufacturing facilities in Shannon spanning over 80,000sq ft and one facility in Poland at 15,000sq ft. In the past 3 years, we have invested €17M in new technologies. 75% of machines are under 5 years old.