Case Study: Embedding a Culture of Continuous Improvement

After taking a Lean Six Sigma approach to solving a particular quality and yield issue in 2018, Smithstown Light Engineering’s lean journey is now focused on continuous improvement and creating a culture that engages employees while enhancing performance.

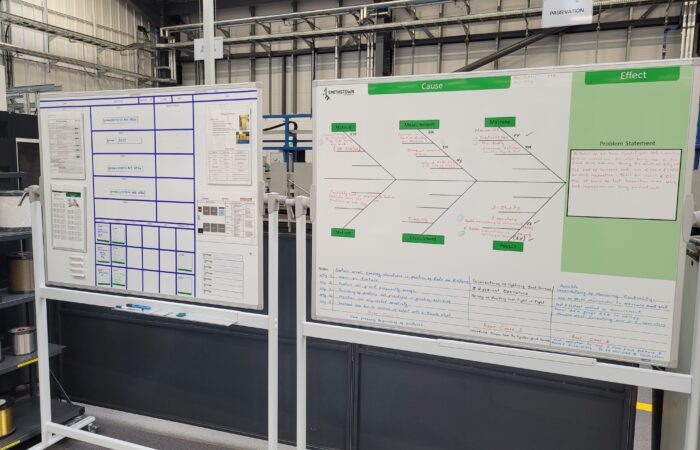

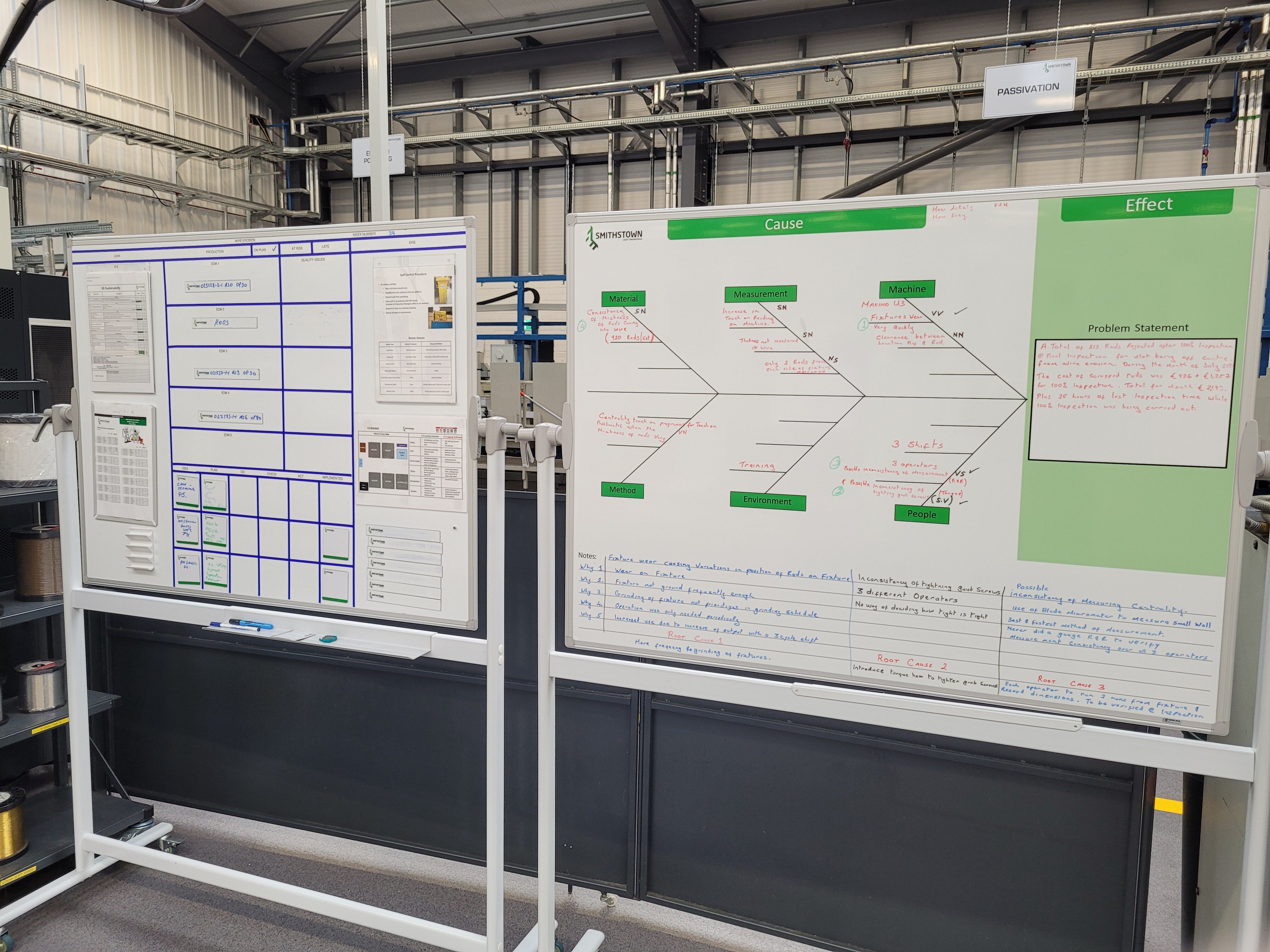

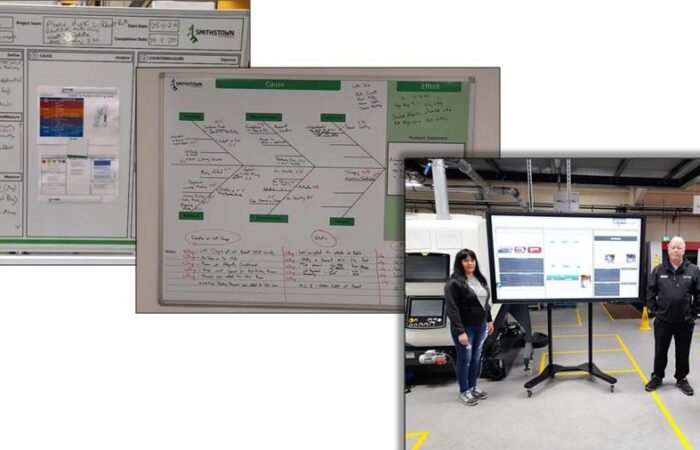

DMAIC Shop Floor Problem Solving Examples: Autonomous shop floor problem solving enables issues to be resolved at the source by those directly involved in the process and allows management to focus on customer needs.

Yellow Belt Projects Examples: Increasing lean knowledge and skillsets plays an important role in establishing and sustaining a Continuous Improvement Culture.

Irish Medtech Association MOR Benchmark Model: To align with medtech standards, we undertook the Mor benchmark model. We use it to measure progress on a yearly basis.

Value Stream Mapping: A key part of our improvement process is to map the values in a process and identify non value adding activities which are then eliminated through PDCA and DMAIC.

Benefits of working with a Lean Contract Partner:

- Reduced lead times

- Reduced costs

- Increased customer satisfaction