Precision Engineering where quality is everything

Precision is the process, the standard, the hallmark of everything we do.

Precision is the process, the standard, the hallmark of everything we do.

We help our customers build life-changing equipment.

We provide contract manufacturing and precision engineering solutions to the top medical device and orthopaedic companies globally.

Comprehensive contract manufacturing solutions for the MedTech sector – a turnkey service from concept and design through to prototyping, machining and validation of medical components and orthopaedic implants.

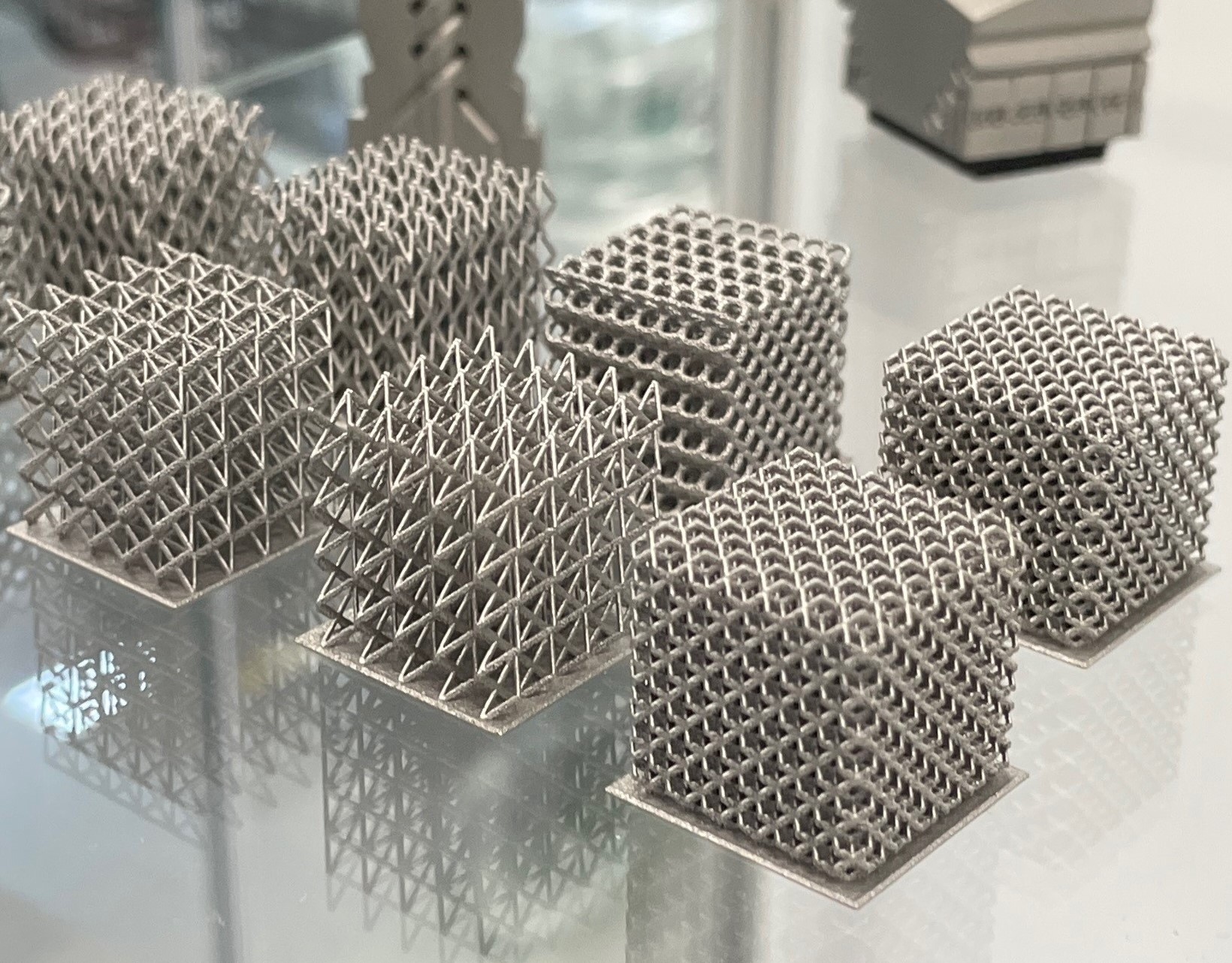

We design and develop medical device components with advanced geometries that are lighter, stronger and more durable and are faster to produce than by conventional means. Smithstown Additive brings the whole additive manufacturing technology process under one roof.

Smithstown’s Wire EDM experience stretches back to 1987, with the then very new technology allowing Smithstown to produce forms in Dies and Mould Cavities to an accuracy that was previously unattainable. We quickly mastered the technology and the Wire EDM department grew to become a backbone within Smithtown’s Medical Device business.

Our FDA registered facilities produce precision components and medical devices and meet all necessary international standards and regulations. Keeping apace with our clients needs, we are committed to the latest quality management system

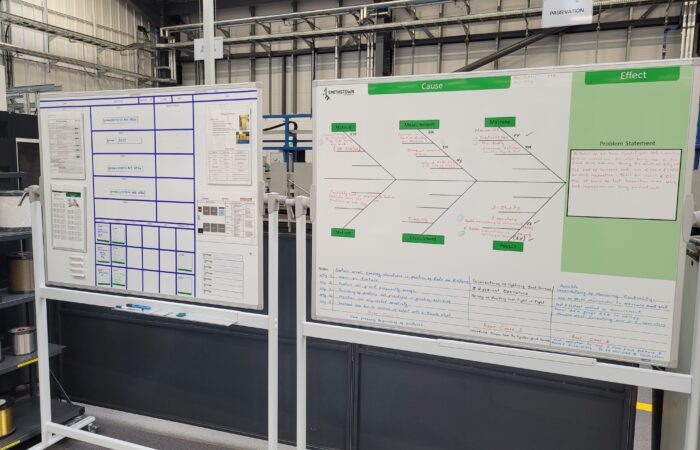

Since 2018, Lean Six Sigma has become an essential part of our manufacturing processes and process improvement strategy. Our Lean projects focus on working together as a team and fostering technical excellence to deliver results.

To maintain our market leading position, we continuously invest in our facilities, equipment and people. We now have two manufacturing facilities in Shannon spanning over 80,000sq ft and one facility in Poland at 50,000sq ft. In the past 3 years, we have invested €17M in new technologies. 75% of machines are under 5 years old.