Our Expertise

High precision medical components for real-life applications.

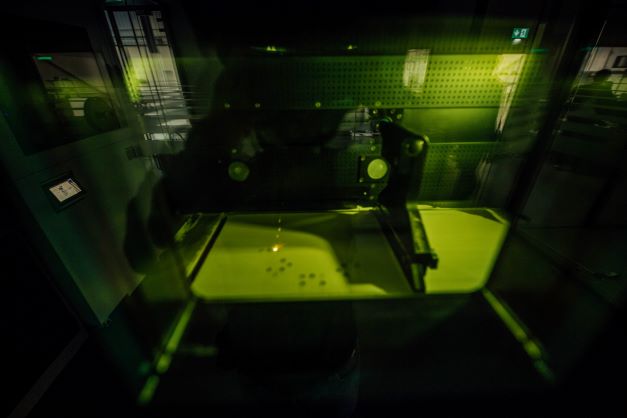

Through our large scale and diverse manufacturing capability, we offer precision engineering, additive manufacturing and contract manufacturing to our clients.

High precision medical components for real-life applications.

Through our large scale and diverse manufacturing capability, we offer precision engineering, additive manufacturing and contract manufacturing to our clients.

Our FDA registered facilities produce precision components and medical devices and meet all necessary international standards and regulations. Keeping apace with our clients needs, we are committed to the latest quality management system

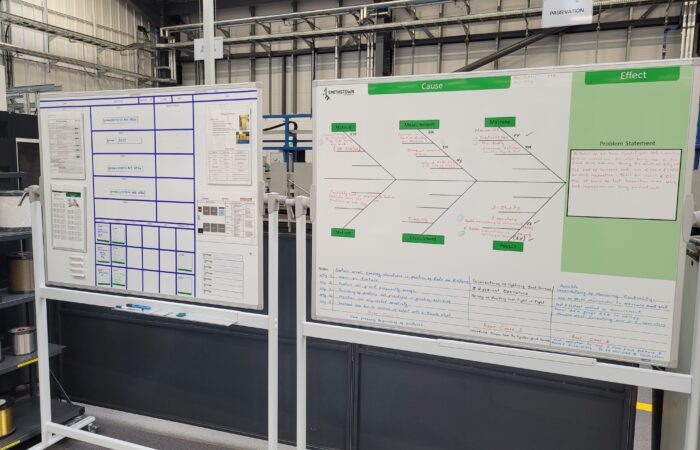

Since 2018, Lean Six Sigma has become an essential part of our manufacturing processes and process improvement strategy. Our Lean projects focus on working together as a team and fostering technical excellence to deliver results.